Choosing a kiln for your classroom is both exciting and a little scary. This is certainly one of the largest capital expenditures an Art Teacher will make in their career, and you want to get it right.

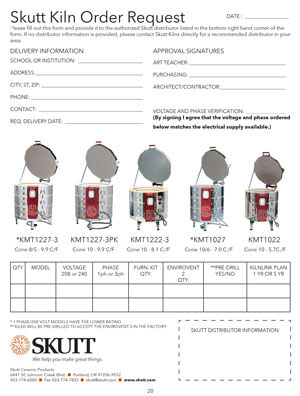

We created a great document that addresses everything you need to know about choosing the right kiln. We suggest you download this Kiln Management pdf here for more detail. It even has an order sheet with signoff spaces for the Architect, Contractor, and Art Teacher to make sure everyone is on the same page. In this article we will go over the high points.

Type of Kiln

There are many styles of kilns to choose from however, most schools choose a top loading electric kiln like the one pictured here for the following reasons:

- They are the best value in terms of cost per cubic/foot.

- Electric kilns are easier to use and safer than gas kilns.

- Contrary to popular belief, they are actually easier to load than frontloading kilns because you do not have to cantilever the weight of heavy shelves away from your body which could place undo stress on your back.

- They have a sectional design that allows them to be easily taken apart to move through doorways and staircases. Frontloading kilns are not only much heavier, many are too large to move through standard doorways and can pose problems when trying to move them into the designated kiln room.

- The controllers on these kilns are designed to be intuitive and are easy to learn, even for teachers who are new to ceramics. The KMT controller pictured here has a kiosk style programming mode that walks the teacher step by step through the process.

Size of Kiln

The size and number of kilns needed for your school will be a direct function of how many students are in the program and the size of the projects they will be making. The most common sizes used in schools are the 10 cu/ft and 7 cu/ft models.

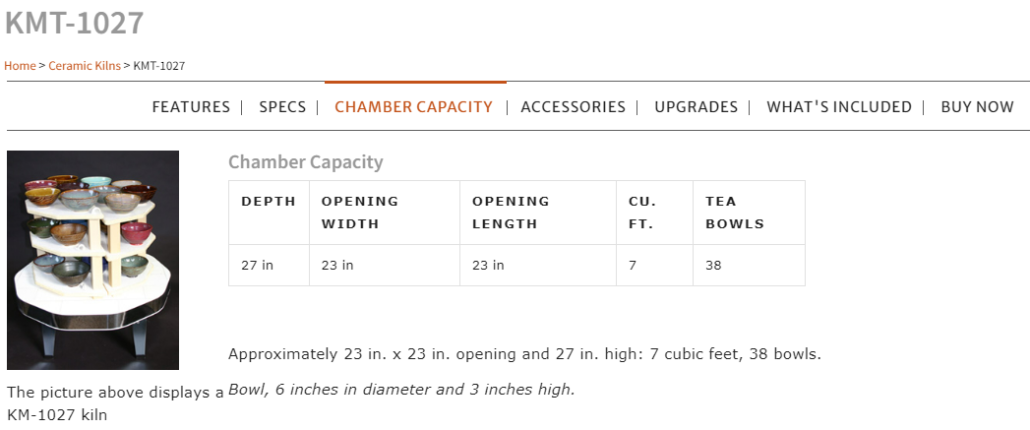

The image below from the Skutt website shows how many 6” bowls can fit in a 7 cu/ft KMT1027 kiln. For this model it is 39. A 10 cu/ft KMT1227 kiln can hold 50 6” tea bowls. Using this image as a tool, you may determine that you will need 2 KMT1227-3 kilns to handle the ware your program of 100 students produces. If that is not in the budget you can just purchase one kiln but will need to do multiple firings.

A 6” tea bowl is a good representation of an average size of a student project. If your students are going to produce larger projects, you will need to take that into account when sizing you kiln.

Sometimes the options for where you can locate the kiln in a school are limited. You will want to be sure the space you choose will allow for the footprint of the kiln plus, the 20” of clearance required by code. The outside measurements of all Skutt Kilns can be found at Build A Spec.

Electrical Specifications

Ordering a kiln that does not match the electrical supply available at the school is one of the most common mistakes purchasing agents make and it is an expensive mistake. If the kiln does not match the supply it needs to be shipped back to the factory at the schools expense. Also, if it is not packed correctly in the original packaging, there is a strong likelihood that the kiln will be damaged in transport and the school would be liable for the entire cost of the kiln.

In most schools the available supplies are:

- 240 Volt/1 Phase

- 208 Volt/1 Phase

- 240Volt/3 Phase

- 208 Volt/3 Phase

Unlike many other electrical appliances, kilns need to be matched to the exact supply they will be hooked up to. Do not let anyone tell you 220 Volt. This is a generic term in the USA for either 208 Volt or 240 Volt. Use the form mentioned earlier in the Kiln Management document to have them sign off and verify the voltage before ordering the kiln.

Venting

There are basically 3 main purposes for venting:

- To remove heat from the room

- To remove fumes created by the firing process from the room

- To create an atmosphere inside the kiln that is beneficial to the ware

If the kiln room exceeds 100 °F the kiln is designed to shut off to protect the electronics in the controller. Most kiln rooms are equipped with an overhead vent sized by an HVAC professional to ensure the room stays below temperatures that could shut down the firing.

A downdraft vent like Skutt’s EnviroVent 2 is installed to take care of the fume removal and improving the chamber atmosphere. The vent is powered by a fan motor mounted to a wall which is connected to a collection cup which fits up under the kiln floor and draws air through small holes drilled in the slab. The fumes are then evacuated from the room much like a clothes dryer.

This process brings fresh oxygen into the kiln chamber which improves combustion and helps to even out temperatures throughout the kiln.

Accessories

You will need a few additional kiln accessories to fire your kiln. To load ware in layers in the kiln you will need a furniture kit. This is composed of various sized refractory posts that are used to stack the shelves along with the shelves themselves. Each kiln model has it’s own recommended furniture kit with the number and size of shelves and posts matched to fit the model.

You will also want to purchase some pyrometric cones which are used in each firing to measure the accuracy of the thermocouple and the uniformity of heat within the kiln chamber.

Want to stay up-to-date with teacher and education-related product news and events? Sign up for our newsletter here, and make sure to check the “school teachers” email list.

Share this post

The post What Are The Best Kilns For Schools? appeared first on Kilns | Ceramic Pottery Kiln, Glass Kiln, Pottery Wheels | Skutt.